Sparkle and Shine: Finding the Best UV Light for Curing Resin Jewelry

Creating stunning resin jewelry requires precision and efficiency. And when it comes to curing resin, the right UV light is your secret weapon. This blog dives into the world of UV lights tailored for resin jewelry, helping you choose the best option to achieve flawless, professional-looking pieces.

Why UV Light Matters for Resin Jewelry:

Traditional air-drying resin can take hours, even days, to fully cure. UV light offers a rapid and consistent curing process, allowing you to:

- Speed Up Production: Cure pieces in minutes, not hours, boosting your creative output.

- Achieve Crystal-Clear Results: UV light ensures even curing, minimizing cloudiness and imperfections.

- Create Durable Pieces: Proper curing enhances resin hardness and longevity.

- Precise Control: Allows for curing in layers, essential for complex jewelry designs.

Key Factors to Consider When Choosing a UV Light:

- Wavelength:

- Most resin jewelry uses UV resins that cure best within the 365nm-405nm range (near UV/visible light). This is the most common range for LED based systems.

- Light Source Type:

- LED UV Lights:

- Ideal for small-scale jewelry making.

- Energy-efficient and long-lasting.

- Provide consistent, focused light.

- Available in various sizes and configurations (handheld, desktop).

- LED UV Lights:

- Intensity/Power:

- Higher wattage or LED output generally means faster curing.

- Consider the thickness of your resin pieces when choosing intensity.

- Size and Portability:

- Choose a size that fits your workspace and allows for easy maneuverability.

- Handheld or small desktop units are ideal for intricate jewelry.

- Timer and Controls:

- A built-in timer helps prevent over-curing and ensures consistent results.

- Adjustable intensity settings offer greater control.

- Safety:

- Look for UV lights with safety certifications.

- Always wear UV-protective eyewear when working with UV light.

Best Practices for UV Curing Resin Jewelry:

- Layer Curing: Cure resin in thin layers to ensure even curing and prevent bubbles.

- Proper Resin Selection: Choose a high-quality UV resin specifically formulated for jewelry making.

- Test and Adjust: Experiment with curing times and intensities to find the optimal settings for your resin and light.

- Cleanliness: Keep your workspace and UV light clean to prevent contamination.

- Post-Curing: Some resins benefit from a short post-curing period in sunlight to further enhance hardness.

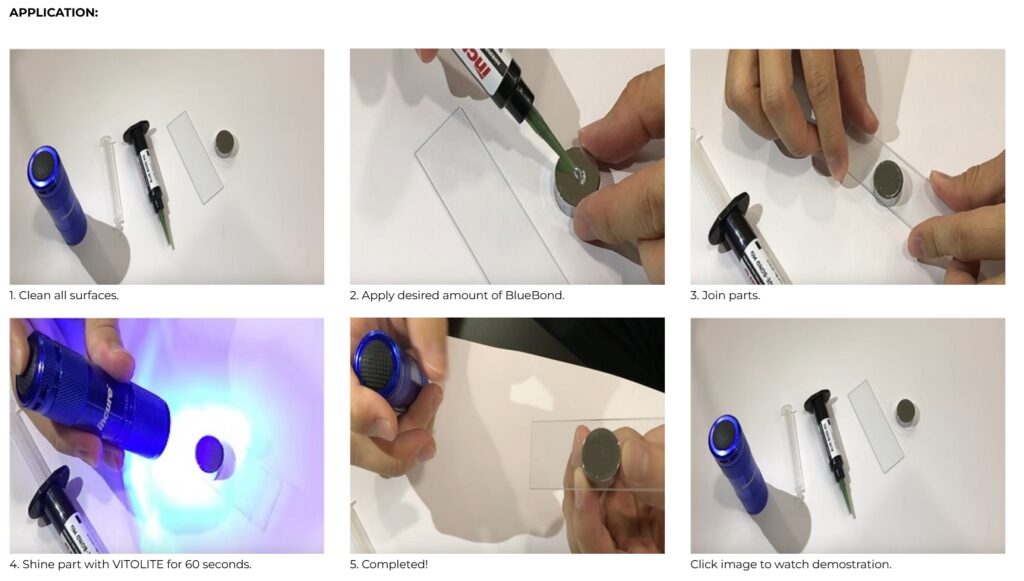

Popular UV Light Options for Resin Jewelry:

- Handheld LED UV flashlights: For small, detailed work.

- Desktop LED UV curing lamps: For larger pieces and batch curing.

Conclusion:

Selecting the best UV light for curing resin jewelry is essential for achieving professional-quality results. By understanding the key factors and best practices, you can create stunning, durable pieces that sparkle and shine.

Contact Us, Incure’s authorized distributor for personalized recommendations. Visit www.blazeasia.com to learn more.