Building with Strength: High-Performance Metal Adhesives for Metal Bonding

In the realm of metal fabrication and assembly, achieving a strong, permanent bond is paramount. Traditional methods like welding and riveting have served their purpose, but they come with limitations. Enter high-performance metal adhesives – a revolutionary solution offering exceptional strength, versatility, and a streamlined bonding process. This blog delves into the world of high-performance metal adhesives, exploring their advantages, functionalities, and diverse applications for robust metal bonding.

Why Choose High-Performance Metal Adhesives?

High-performance metal adhesives offer numerous advantages over traditional joining methods:

- Strong and Reliable Bonds: These adhesives can create bonds that rival the strength of welds, ensuring long-lasting and secure metal connections.

- Versatility: Metal adhesives can bond a wide range of metals, including dissimilar metals that are difficult or impossible to weld.

- Uniform Stress Distribution: Adhesives distribute stress more evenly across the bonded area compared to welds, potentially reducing the risk of stress concentrations and fractures.

- Sealing and Gap Filling: Certain adhesives can fill gaps and imperfections between metal surfaces, creating a watertight and airtight seal.

- Lightweight and Streamlined Assembly: Adhesives eliminate the need for heat and bulky equipment, simplifying the assembly process and reducing weight in structures.

- Reduced Distortion: Metal bonding with adhesives minimizes heat distortion compared to welding, preserving the dimensional integrity of components.

Types of High-Performance Metal Adhesives

Several types of high-performance metal adhesives cater to different bonding needs:

- Epoxy Adhesives: Two-part epoxies offer exceptional strength, chemical resistance, and versatility, making them suitable for a wide range of metal bonding applications.

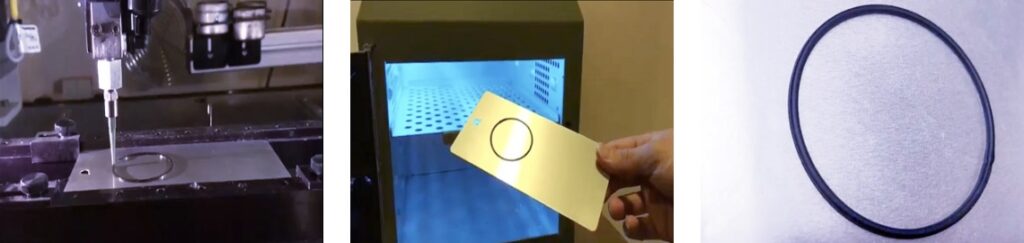

- Anaerobic Adhesives: These one-part adhesives cure in the absence of air, ideal for filling gaps and bonding tight-fitting metal parts.

- Acrylic Adhesives: Known for their fast curing speeds, flexibility, and good strength, acrylic adhesives are well-suited for bonding dissimilar metals or applications requiring some degree of joint movement.

- Structural Acrylic Adhesives: A high-strength variation of acrylic adhesives, offering exceptional bond strength and durability for demanding applications.

- Cyanoacrylate Adhesives (Super Glues): Fast-curing and well-suited for small parts, super glues require careful application due to their rapid setting time.

Applications for High-Performance Metal Adhesives

The versatility and strength of high-performance metal adhesives make them ideal for various applications in diverse industries:

- Automotive Assembly: Bonding body panels, spoilers, and interior components for a lightweight and streamlined design.

- Aerospace Manufacturing: Creating strong and reliable bonds in aircraft structures where weight reduction is crucial.

- Construction: Adhering metal panels, cladding systems, and other building components.

- Appliance Manufacturing: Bonding metal parts in appliances like refrigerators, dishwashers, and washing machines.

- Electronics Manufacturing: Securing heat sinks, EMI shielding components, and other metal parts in electronic devices.

- Metal Fabrication: Joining dissimilar metals, filling gaps, and creating leak-proof seals in various metal structures.

Choosing the Right High-Performance Metal Adhesive

Selecting the optimal adhesive for your application requires considering several factors:

- Substrate Compatibility: Ensure the adhesive is formulated for the specific metals you are bonding.

- Strength Requirements: Choose an adhesive with the necessary bond strength to withstand the expected loads and stresses.

- Environmental Conditions: Consider factors like temperature, moisture, and chemical exposure to select an adhesive with appropriate resistance.

- Desired Working Time: Choose an adhesive with an open time (working time) that allows for proper positioning and manipulation of parts before curing commences.

- Curing Speed: Select a curing speed that aligns with your production workflow. Some applications require fast-curing adhesives for high throughput, while others may benefit from slower curing times for precise positioning.

Embrace a New Era of Metal Bonding

High-performance metal adhesives offer a game-changing solution for metal fabrication and assembly. Their exceptional strength, versatility, and ability to create lightweight, stress-resistant bonds make them a compelling choice across diverse industries. So, if you’re looking for a reliable and innovative way to join metals, consider incorporating high-performance metal adhesives into your toolbox and empower your creations with lasting strength.