UV Curing Systems: Accelerating Production and Enhancing Quality

Revolutionize your manufacturing process with Incure’s advanced UV curing systems. This guide explores the key benefits of UV curing technology and how Incure’s customizable solutions can boost productivity, enhance product quality, and minimize your environmental impact.

What are the Advantages of UV Curing Systems?

UV curing technology utilizes ultraviolet (UV) light to instantly cure resins, offering a fast, efficient, and environmentally friendly alternative to traditional curing methods. Here’s why it’s transforming industries:

- Rapid Curing for Increased Productivity: Experience significantly faster production times compared to conventional methods, maximizing your output.

- High-Quality Results & Superior Finish: Achieve exceptional durability, chemical resistance, and a superior finish with UV cured products.

- Energy Efficiency & Cost Savings: Reduce energy consumption and lower your operating costs with efficient UV curing systems.

- Reduced Environmental Impact & Sustainability: Eliminate the use of volatile organic compounds (VOCs) and minimize your environmental footprint.

- Versatility Across Industries & Applications: Ideal for a wide range of applications, including coatings, adhesives, inks, 3D printing, and more.

Incure: Your Partner in UV Curing Excellence

Incure is a leading provider of advanced UV curing solutions, offering expertise and innovative technology to help you:

- Optimize Manufacturing Processes: Maximize efficiency, productivity, and throughput.

- Achieve Superior Product Quality: Meet the highest industry standards and exceed customer expectations.

- Reduce Environmental Impact: Contribute to a more sustainable future with eco-friendly curing solutions.

Our Comprehensive UV Curing Solutions:

- Customizable Systems: We design and manufacture tailored solutions to meet your unique production needs and specific applications.

- High-Performance UV Lamps: Utilize our powerful and reliable UV lamps for consistent, efficient, and long-lasting curing performance.

- Advanced & User-Friendly Control Systems: Gain precise control over the curing process with our intuitive control systems.

- Expert Technical Support: Benefit from our team’s in-depth knowledge and comprehensive technical support, from design and installation to ongoing maintenance.

Key Factors to Consider When Selecting a UV Curing System:

- Power Output & Lamp Intensity: Choose the optimal lamp power to achieve the desired curing speed and intensity for your materials.

- Wavelength Range & Resin Compatibility: Select lamps with the appropriate wavelength for your specific resin type to ensure optimal curing.

- Lamp Configuration & Uniformity: Customize the lamp arrangement to guarantee uniform and efficient curing across your product’s surface.

- Conveyor System Integration & Efficiency: Invest in a reliable and efficient conveyor system for smooth and consistent product handling and seamless integration.

- Intuitive Control System & Process Monitoring: Select a user-friendly control system for easy operation, precise process adjustments, and real-time monitoring.

Invest in Incure’s UV Curing Technology for a Competitive Edge:

Partnering with Incure empowers you to:

- Accelerate Production Timelines & Increase Output: Maximize your efficiency and meet market demands.

- Enhance Product Quality & Achieve Exceptional Performance: Deliver superior products that stand out.

- Reduce Your Environmental Footprint & Promote Sustainability: Minimize your impact and contribute to a greener future.

Optimizing Your UV Curing Process: Best Practices

- Regular Maintenance for Longevity: Implement a regular maintenance schedule to ensure optimal performance and extend the lifespan of your UV curing system.

- Proper Ventilation for a Safe Environment: Ensure adequate ventilation to maintain a safe and healthy working environment.

- Prioritize Safety with Proper Precautions: Always wear appropriate safety gear, including protective eyewear and gloves, when working with UV light.

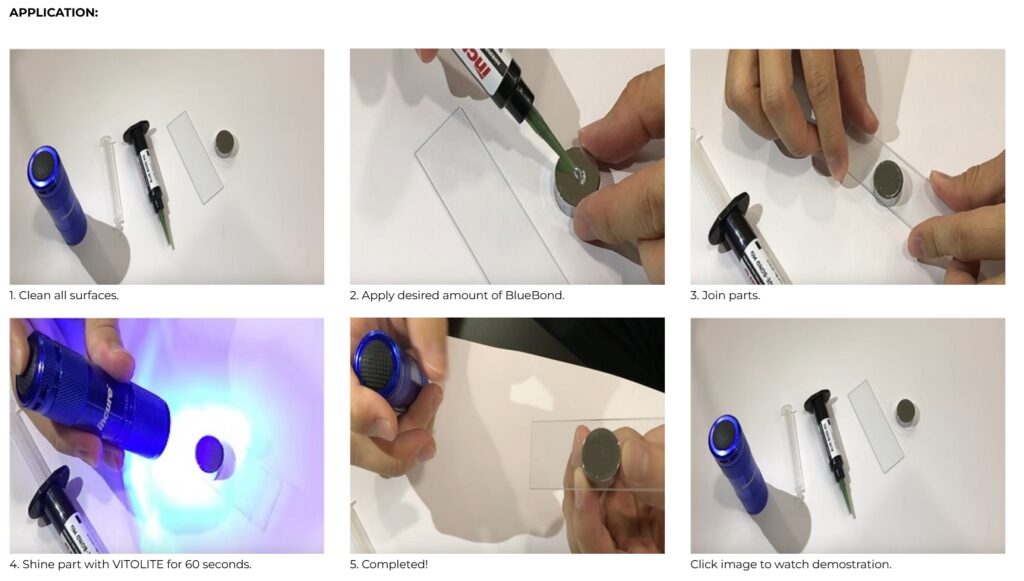

Tackle adhesive curing in electronics and other challenging applications with Incure’s lineup of adjustable, High-Intensity UV Spot Lamps. Discover precise curing, unmatched performance, and expert support. Contact Us, Incure’s authorized distributor for personalized recommendations on wavelength and cure times. Visit www.blazeasia.com to learn more.