Boost your production efficiency with a reliable glue dispenser machine. Learn about the different types, benefits, and how to choose the right machine for your specific needs.

A Guide to Glue Dispenser Machines

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. For businesses that rely heavily on adhesives, a reliable glue dispenser machine can significantly improve production speed, accuracy, and overall output.

What are Glue Dispenser Machines?

Glue dispenser machines are automated systems designed to accurately and consistently apply adhesives to various substrates. These machines come in a wide range of types and configurations to suit different applications, from simple bead dispensing to complex pattern applications.

Types of Glue Dispenser Machines:

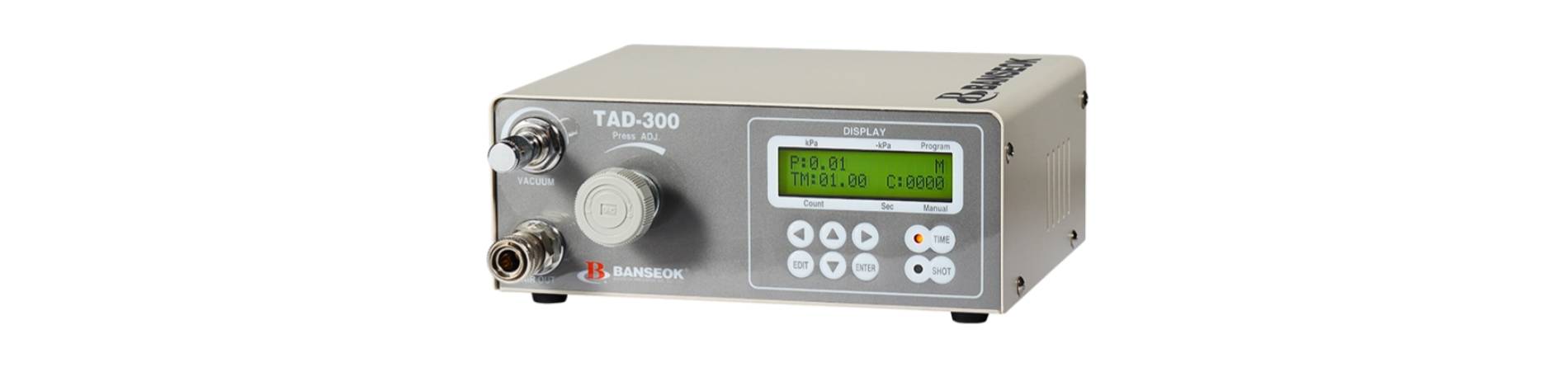

- Pneumatic Dispensers: Utilize compressed air to dispense glue, offering good control and flexibility.

- Electric Dispensers: Use electric motors to drive the dispensing process, providing precise control and repeatability.

- Hot Melt Glue Dispensers: Heat glue to a molten state for application, resulting in faster drying times and stronger bonds.

- Two-Component Dispensers: Mix and dispense two-part adhesives, such as epoxy, for applications requiring high strength and durability.

Benefits of Using Glue Dispenser Machines:

- Increased Efficiency: Automated dispensing significantly increases production speed and throughput.

- Improved Accuracy and Consistency: Ensures precise and consistent glue application, minimizing waste and improving product quality.

- Reduced Labor Costs: Automates manual glue application tasks, freeing up workers for other duties.

- Enhanced Safety: Eliminates the risk of manual handling of adhesives, improving workplace safety.

- Improved Product Quality: Consistent glue application leads to stronger, more reliable bonds and fewer product defects.

- Versatility: Available in various configurations to suit a wide range of applications and industries.

Choosing the Right Glue Dispenser Machine:

Selecting the appropriate glue dispenser machine depends on several factors, including:

- Application Requirements: The specific type of adhesive and the desired application pattern.

- Production Volume: The volume of production and the required throughput.

- Budget: The available budget for the machine and associated equipment.

- Maintenance Requirements: The ease of maintenance and the availability of spare parts.

Conclusion:

Investing in a high-quality glue dispenser machine can significantly enhance the efficiency and productivity of your manufacturing operations. By carefully considering your specific needs and choosing the right machine for your application, you can optimize your production processes and gain a competitive edge.

Contact us today to learn more about how Blaze Technology can revolutionize your glue dispensing and help you achieve your project goals. Visit www.blazeasia.com to learn more or request a quote.

Last updated on February 20th, 2025 at 12:39 am