Discover modern glass bonding systems for electronics, architecture, and more. Achieve seamless bonds with high strength and environmental resistance.

In today’s world, glass is more than just a transparent barrier. From sleek smartphone screens to complex architectural structures, glass plays a crucial role in countless applications. But how do we securely and seamlessly join glass components? The answer lies in advanced glass bonding systems. This blog explores the benefits, applications, and key considerations when selecting the right system for your needs.

Beyond Traditional Methods: The Evolution of Glass Bonding

Traditional methods like mechanical fasteners or simple adhesives often fall short when it comes to glass bonding. They can create stress points, visible seams, or lack the necessary durability. Modern glass bonding systems offer a superior approach, leveraging advanced technologies to create strong, invisible, and long-lasting bonds.

Key Benefits of Advanced Glass Bonding Systems:

- High Bond Strength: Engineered adhesives and curing processes create exceptionally strong bonds, capable of withstanding significant stress.

- Optical Clarity: Many systems utilize optically clear adhesives, ensuring seamless and invisible bonds.

- Design Flexibility: Glass bonding allows for complex and innovative designs that would be impossible with traditional methods.

- Durability and Longevity: Advanced adhesives are resistant to environmental factors like UV radiation, moisture, and temperature fluctuations.

- Reduced Stress: Uniform stress distribution minimizes the risk of glass breakage.

- Aesthetic Appeal: Seamless bonds enhance the visual appeal of glass products.

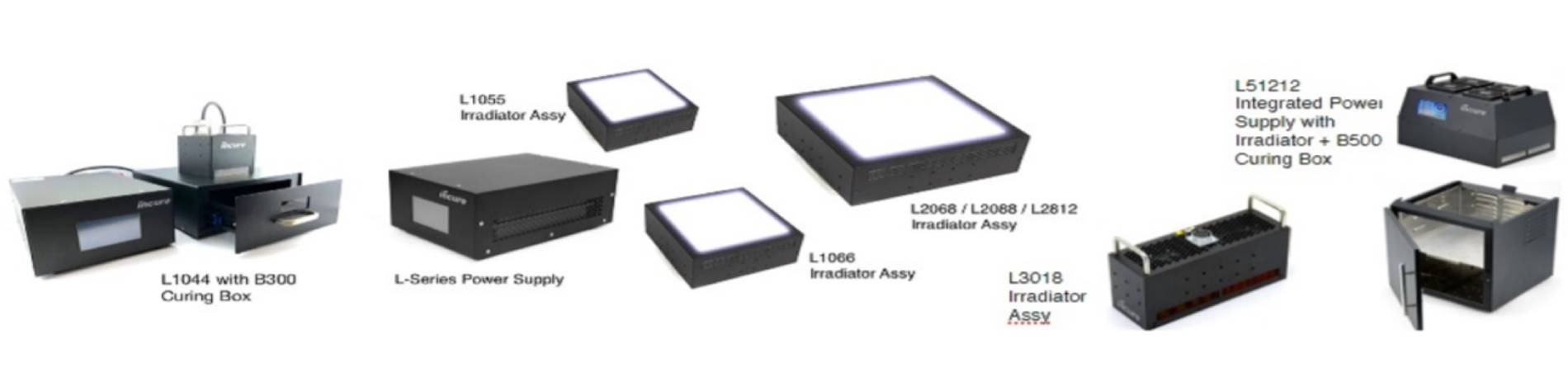

| Configuration | L1044 | L1055 | L1066 | L2068 | L2088 | L2812 | L3018 | L51212 | |||||||||||

| Type of Lamp | LED Flood, Programmable | ||||||||||||||||||

Intensity in mW/cm2 (Measured with EIT Power Puck Distance from Lamp Base) | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | UVA | UVV | |||

| @0.5 | 2750 | 139 | 2200 | 112 | 1930 | 91 | 1650 | 70 | 1380 | 59 | 1240 | 56 | 8750 | 1380 | 70 | ||||

| @1.0 | 2540 | 127 | 2040 | 105 | 1780 | 87 | 1530 | 69 | 1270 | 58 | 1150 | 55 | 8000 | 1270 | 64 | ||||

| @1.5″ | 2420 | 120 | 1940 | 99 | 1700 | 84 | 1460 | 68 | 1210 | 57 | 1090 | 54 | 7500 | 1210 | 60 | ||||

| @2.0″ | 2370 | 116 | 1900 | 93 | 1660 | 81 | 1430 | 67 | 1190 | 56 | 1070 | 53 | 7200 | 1190 | 58 | ||||

| @2.5″ | 2260 | 111 | 1810 | 87 | 1590 | 78 | 1360 | 66 | 1130 | 55 | 1020 | 52 | 6900 | 1130 | 56 | ||||

| @3.0″ | 2070 | 101 | 1660 | 82 | 1450 | 75 | 1250 | 65 | 1040 | 54 | 940 | 51 | 6750 | 1040 | 51 | ||||

| @4.0″ | 1550 | 82 | 1240 | 77 | 1090 | 72 | 930 | 64 | 780 | 53 | 700 | 50 | 6600 | 780 | 41 | ||||

| Intensity Adjustment | LED Controller | ||||||||||||||||||

| Available Wavelengths | 365 , 395, 405 | ||||||||||||||||||

| Working Distance | 1.5” – 4.0” | ||||||||||||||||||

| Expected Bulb Life* | > 20,000 hrs | ||||||||||||||||||

| Intensity Decay over Life | 20% | ||||||||||||||||||

| Static Uniformity @ 2.0” | 0.78 | ||||||||||||||||||

| Dynamic Uniformity @ 3.0” | 0.90 | ||||||||||||||||||

| Curing Area | 4” x 4” | 5” X 5” | 6” X 6” | 6” X 8” | 8” X 8” | 8” X 12” | 1” X 8” | 12” X 12” | |||||||||||

| Curing Box Adjustable Heights (optional purchase) | 3.5” Max Distance | ||||||||||||||||||

| Temperature Management | Forced Air with Standby Mode | ||||||||||||||||||

| Power Input | 100-240V, 50/60Hz, Auto-Ranging | ||||||||||||||||||

| External Control Port | LCD Programmable Panel | ||||||||||||||||||

| Ordering Part Number | L1044-365 L1044-395 L1044-405 | L1055-365 L1055-395 L1055-405 | L1066-365 L1066-395 L1066-405 | L2068-365 L2068-395 L2068-405 | L2088-365 L2088-395 L2088-405 | L2812-365 L2812-395 L2812-405 | L3018-365 L3018-395 L3018-405 | L21212-365 L21212-395 L21212-405 | |||||||||||

| Irradiator Dimension / Weight | 5.1” x 5.1” x 6.4” (4.6 lb) | 6.1” x 6.1” x 6.4” (5.9 lb) | 7.1” x 7.1” x 6.4” (5.9 lb) | 7.6” x 9.1” x 6.4” (9.2 lb) | 9.9” x 9.9” x 3.95” (15.5 lb) | 9.1” x 18.1” x 6.4” (18.4 lb) | 10.3” x 3.6” x 4.0” (5.5 lb) | 14.7” x 14.2” x 21.6” (78 lb) | |||||||||||

| Controller Dimension / Weight | 12.9” x 5.2” x 9” (17.1 lb) | 13” x 9.1” x 5.2” (14.5 lb) | |||||||||||||||||

| Curing Drawer / Box(Optional Purchase,Unless Specified) | B300 | Request For More Information | Included | ||||||||||||||||

| Curing Drawer / Box Dimension | 12” x 12” x 5.5” | 12” x 12” x 5.5” | 12” x 12” x 5.5” | 12” x 12” x 5.5” | 12” x 12” x 5.5” | ||||||||||||||

| Interlock Safety Feature | Integrated When Mounted on B300 Curing Drawer | ||||||||||||||||||

| C9000 TM Conveyor Mounting | Yes | No | Not Applicable | ||||||||||||||||

Applications Across Diverse Industries:

Glass bonding systems are used in a wide range of industries:

- Electronics: Bonding touchscreens, display panels, and other components in smartphones, tablets, and other devices.

- Architecture: Creating structural glass walls, facades, and skylights.

- Automotive: Bonding windshields, rear windows, and other glass components.

- Medical Devices: Bonding glass components in diagnostic equipment and other medical devices.

- Optical Instruments: Bonding lenses, prisms, and other optical components.

- Furniture and Interior Design: Creating glass furniture, partitions, and decorative elements.

- Solar Panels: Bonding glass layers in photovoltaic modules.

Key Considerations When Choosing a Glass Bonding System:

- Adhesive Type: Select an adhesive that is compatible with the specific glass materials and application requirements. Consider factors like viscosity, curing method, and optical properties.

- Curing Method: Choose a curing method that is suitable for your production environment and application. Options include UV curing, heat curing, and moisture curing.

- Surface Preparation: Proper surface preparation is essential for achieving a strong bond. Consider cleaning, priming, and surface activation techniques.

- Dispensing and Application Equipment: Select dispensing and application equipment that can accurately and consistently apply the adhesive.

- Bond Strength and Durability: Ensure the system meets the required bond strength and durability specifications.

- Environmental Resistance: Consider the environmental conditions the bonded glass will be exposed to and choose an adhesive that can withstand those conditions.

- Cost-Effectiveness: Balance performance requirements with cost considerations.

Creating Stronger Connections with Advanced Technology:

Advanced glass bonding systems are revolutionizing the way we join glass components. By offering superior strength, clarity, and design flexibility, these systems are enabling innovative applications across a wide range of industries. Investing in a high-quality glass bonding system can significantly enhance the performance and aesthetic appeal of your glass products.

See how Incure UV LED flood lamps provide broad, uniform coverage – visit our showroom and experience the difference today!