Discover how fluid dispensing machines ensure precision in manufacturing. Explore applications, benefits, and crucial factors for choosing the right system.

In today’s fast-paced manufacturing landscape, precision and efficiency are paramount. Whether you’re assembling intricate electronics, applying adhesives in medical devices, or sealing components in automotive production, accurate fluid dispensing is crucial. That’s where a fluid dispensing machine becomes an indispensable asset. This blog explores the benefits, applications, and key considerations when choosing a fluid dispensing machine.

The Power of Precision: Understanding Fluid Dispensing

Fluid dispensing machines are designed to apply precise amounts of liquids, adhesives, sealants, and other fluids with unparalleled accuracy and consistency. Unlike manual application, which can lead to inconsistencies and waste, automated dispensing ensures:

- Consistent Dosing: Precise control over the amount of fluid dispensed, minimizing variations and ensuring uniform application.

- Accurate Placement: Precise positioning of the dispensing nozzle, allowing for accurate application in even the most intricate designs.

- Reduced Waste: Optimized fluid usage, minimizing waste and reducing material costs.

- Increased Throughput: Automated dispensing significantly speeds up production, increasing efficiency and reducing cycle times.

- Improved Quality: Consistent and accurate dispensing leads to higher product quality and reduced defects.

Applications Across Industries:

Fluid dispensing machines are used in a wide range of industries, including:

- Electronics Manufacturing: Applying solder paste, adhesives, and conformal coatings to PCBs and electronic components.

- Medical Device Manufacturing: Dispensing adhesives for bonding medical devices, applying coatings to implants, and filling syringes.

- Automotive Manufacturing: Applying adhesives for bonding components, sealing gaskets, and applying lubricants.

- Aerospace Manufacturing: Dispensing adhesives and sealants for bonding and sealing aircraft components.

- General Manufacturing: Applying adhesives, sealants, lubricants, and other fluids in various assembly and manufacturing processes.

Key Considerations When Choosing a Fluid Dispensing Machine:

- Fluid Type and Viscosity: Consider the type and viscosity of the fluid you’ll be dispensing.

- Dispensing Accuracy and Repeatability: Evaluate the machine’s accuracy and repeatability to ensure it meets your requirements.

- Dispensing Speed and Throughput: Determine the required dispensing speed and throughput to meet your production needs.

- Automation Level: Choose a machine with the appropriate level of automation for your application.

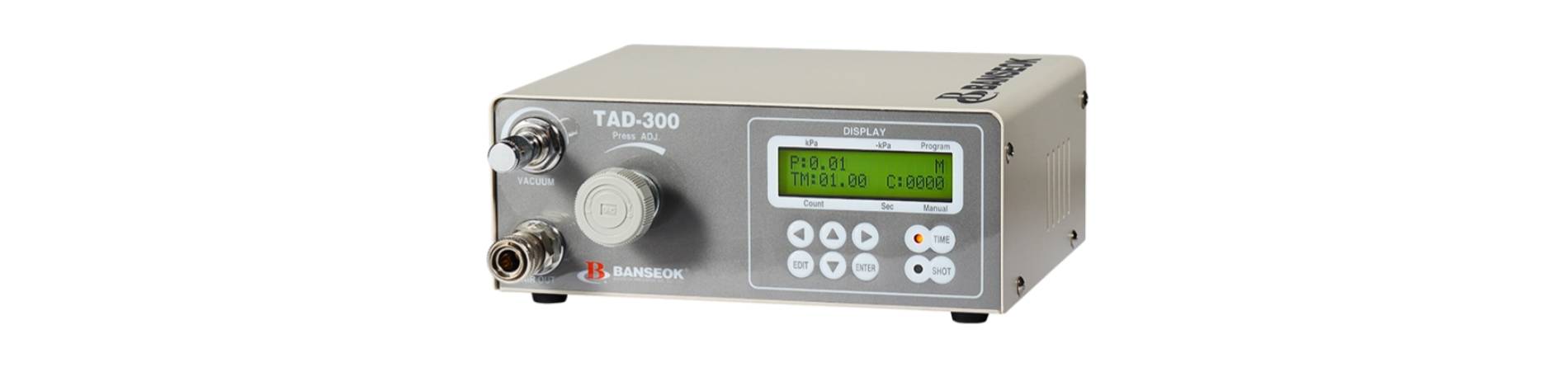

- Software and Control System: Evaluate the machine’s software and control system for ease of use and functionality.

- Maintenance and Support: Consider the availability of maintenance and support services.

- Budget: Determine your budget and choose a machine that offers the best value for your investment.

- Dispensing Method: common dispensing methods include time/pressure, jetting, and screw valve.

Investing in Efficiency and Quality:

A fluid dispensing machine is a valuable investment for any manufacturing operation that requires precise and consistent fluid application. By automating the dispensing process, you can improve product quality, increase efficiency, and reduce costs.

In conclusion: Fluid dispensing machines are an essential tool for modern manufacturing. They provide the precision, consistency, and efficiency needed to meet the demands of today’s competitive market. By carefully considering your specific needs and choosing the right machine, you can unlock significant benefits and achieve new levels of productivity.