Boost production, enhance quality, and cut costs with Incure’s UV curing conveyor systems. Our customizable solutions offer precise control and superior performance for a wide range of industries. Learn more about how UV curing can revolutionize your manufacturing process.

Revolutionize your production process with Incure’s advanced UV curing conveyor systems. This comprehensive guide explores the key benefits of UV curing technology and how Incure’s customizable solutions can boost productivity, enhance product quality, and minimize waste in your manufacturing operations.

What are the Advantages of UV Curing Conveyor Systems?

UV curing conveyor systems offer a rapid, precise, and continuous method for curing resin-based materials, transforming manufacturing processes. Here’s how:

- Increased Throughput: Continuous curing eliminates batch downtime, dramatically accelerating production cycles and maximizing output.

- Superior Product Quality: Consistent UV exposure ensures uniform curing, leading to improved product quality, reduced defects, and greater consistency.

- Enhanced Efficiency & Cost Savings: Reduced energy consumption, minimized material waste, and faster processing times translate to significant cost savings and a smaller environmental footprint.

- Versatility Across Industries: UV curing conveyor systems are adaptable to a wide range of industries, including electronics, automotive, printing, packaging, and more.

- Tailored Solutions for Your Needs: Customizable systems can be designed to meet specific production requirements and seamlessly integrate into existing workflows.

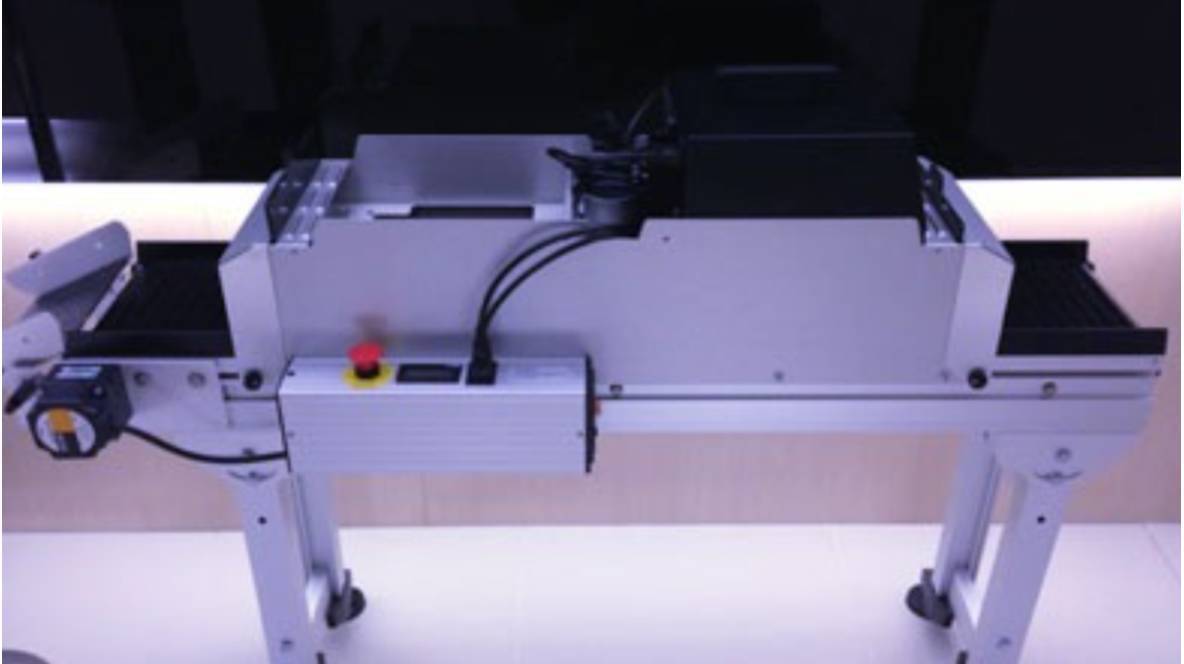

Incure: Your Partner for High-Performance UV Curing Solutions

Incure provides a comprehensive range of high-performance UV curing conveyor systems engineered to optimize your production efficiency:

- Customizable Systems: We specialize in designing and manufacturing custom systems tailored to your unique needs, production volumes, and specific applications.

- Powerful UV Lamps: Our cutting-edge UV lamps deliver exceptional curing power and ensure consistent, reliable results.

- Advanced Control Systems: Intuitive control systems provide precise control over crucial curing parameters, including conveyor speed, lamp intensity, and exposure time.

- Unparalleled Technical Support: Our team of experienced engineers offers comprehensive technical support, from system design and installation to ongoing maintenance and optimization.

Choosing the Right UV Curing Conveyor System: Critical Considerations

Selecting the optimal UV curing system is essential for maximizing performance and return on investment (ROI). Key factors to consider include:

- Conveyor Belt Material: Choosing a belt material compatible with your specific application and product ensures smooth, reliable product transport.

- Conveyor Speed Optimization: Precisely control conveyor speed to achieve desired curing times while maintaining optimal product quality.

- Lamp Configuration for Uniformity: Select the ideal lamp configuration to guarantee uniform UV exposure across the entire product surface.

- Efficient Cooling System: An effective cooling system is crucial for maintaining lamp performance, preventing overheating, and extending lamp life.

- User-Friendly Control System: A well-designed control system enables precise adjustments and real-time monitoring of the curing process.

Invest in Incure’s UV Curing Technology for a Competitive Edge

Partnering with Incure for your UV curing conveyor system needs offers significant advantages:

- Boost Production Throughput: Maximize your output and meet growing demands.

- Elevate Product Quality & Consistency: Achieve superior, consistent results.

- Reduce Operating Costs: Minimize energy consumption, waste, and downtime.

- Gain a Competitive Advantage: Streamline your operations and stay ahead of the curve.

Optimizing Your UV Curing Process: Best Practices

- Regular Maintenance is Key: Implement a consistent maintenance schedule to ensure optimal system performance, longevity, and minimize downtime.

- Proper Ventilation for Safety: Ensure adequate ventilation to effectively remove heat and fumes generated during the curing process.

- Prioritize Safety: Always adhere to safety guidelines and wear appropriate personal protective equipment (PPE) when working with UV light.

Contact Us for personalized guidance and tailored recommendations. Visit www.blazeasia.com to learn more or request a quote.

Last updated on January 31st, 2025 at 04:39 am