UV Flood Curing Systems

Incure UV Flood Lamps offer high-intensity, broad-beam UV curing for efficient and consistent results across various industries. Ideal for adhesives, coatings, and inks, they ensure uniform curing on large or irregular surfaces, boosting production and product quality.

In today’s fast-paced manufacturing and professional environments, efficiency and precision are paramount. Whether you’re working with adhesives, coatings, inks, or other UV-curable materials, achieving consistent and reliable results is crucial. That’s where Incure UV Flood Lamps come in, offering a powerful and versatile solution for a wide range of applications.

What are Incure UV Flood Lamps?

Incure UV Flood Lamps are high-intensity ultraviolet light sources designed for curing UV-sensitive materials over larger areas. Unlike focused UV LED systems, flood lamps provide a broad, even distribution of UV energy, ensuring uniform curing across the entire surface. This makes them ideal for projects requiring consistent results on larger or irregularly shaped objects.

Benefits of Using Incure UV Flood Lamps:

- Fast and Efficient Curing: High-intensity UV output translates to rapid curing times, significantly increasing production throughput and reducing downtime.

- Uniform and Consistent Results: The broad beam pattern ensures even curing across the entire surface, eliminating inconsistencies and defects.

- Versatility for Diverse Applications: Incure lamps are suitable for a wide range of UV-curable materials, including adhesives, coatings, inks, resins, and more.

- Scalability for Various Project Sizes: Available in different sizes and configurations, Incure lamps can be tailored to meet the specific needs of your project, from small-scale applications to large-volume production.

- Durability and Reliability: Built with robust components, Incure lamps are designed for long-lasting performance in demanding industrial environments.

- Improved Product Quality: Consistent and thorough curing results in stronger bonds, more durable coatings, and enhanced product aesthetics.

Applications Across Industries:

Incure UV Flood Lamps find applications in numerous industries, including:

- Automotive: Curing adhesives for bonding components, sealing, and coating applications.

- Electronics: Curing adhesives for component assembly, conformal coatings, and potting.

- Medical Device Manufacturing: Curing adhesives for bonding medical devices, coatings for catheters, and sterilization processes.

- Printing and Packaging: Curing UV inks and coatings on labels, packaging materials, and printed electronics.

- Woodworking and Furniture: Curing UV coatings for finishing furniture, flooring, and other wood products.

- Aerospace: Curing adhesives for bonding composite materials and sealing applications.

- General Manufacturing: Curing adhesives for product assembly, bonding dissimilar materials, and applying protective coatings.

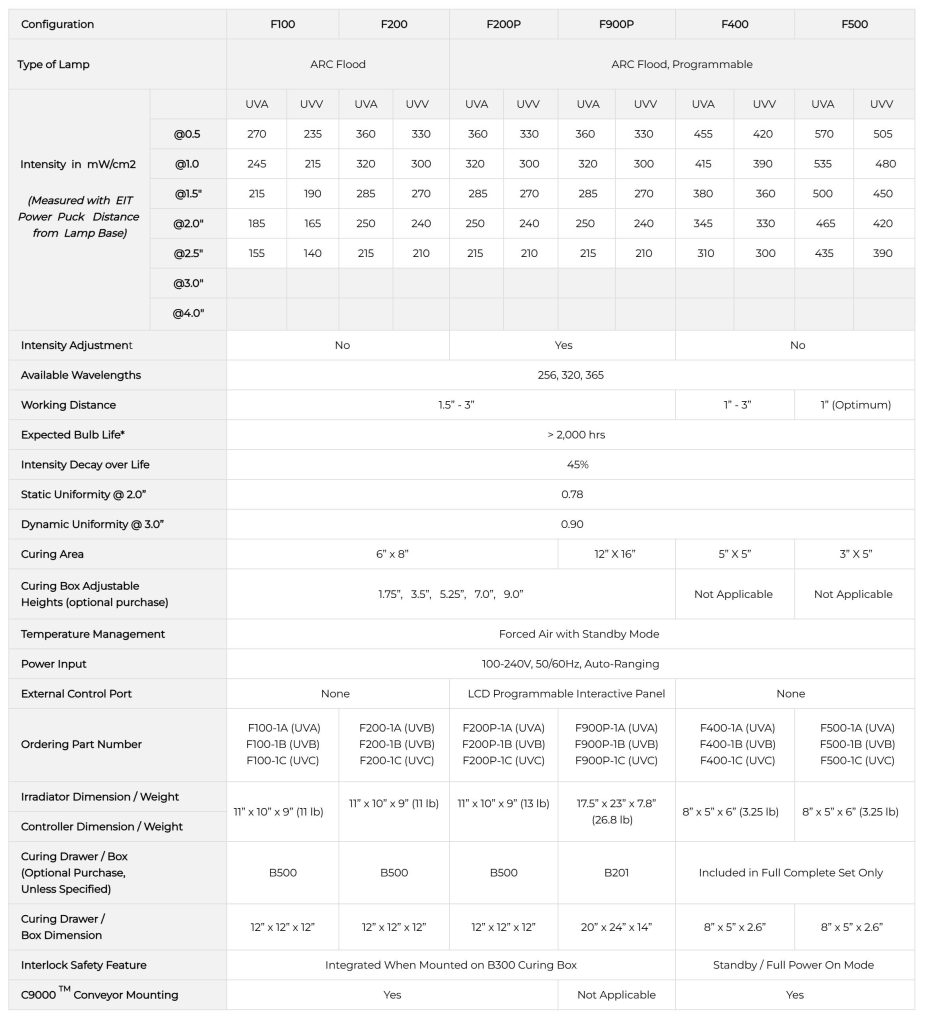

Choosing the Right Incure UV Flood Lamp for Your Project:

Selecting the appropriate Incure UV Flood Lamp depends on several factors, including:

- The type of UV-curable material being used: Different materials require specific wavelengths and intensities of UV light.

- The size and shape of the object being cured: Larger or irregularly shaped objects may require a wider beam pattern.

- The desired curing time: Higher intensity lamps can achieve faster curing times.

- The specific application requirements: Factors such as temperature control, automation, and safety considerations may influence the choice of lamp.

Invest in Incure UV Flood Lamps and experience the benefits of fast, efficient, and reliable UV curing. Contact us today to learn more about our products and how they can help you achieve your project goals.