Best Pump for High Viscosity Fluids

PCP-20-10: High-viscosity 20L pail pump for direct dispensing. Eliminate waste & bubbles with precise application. Ideal for industrial sealing & bonding.

Maximize Efficiency with the PCP-20-10 High-Viscosity 20L Pail Pump

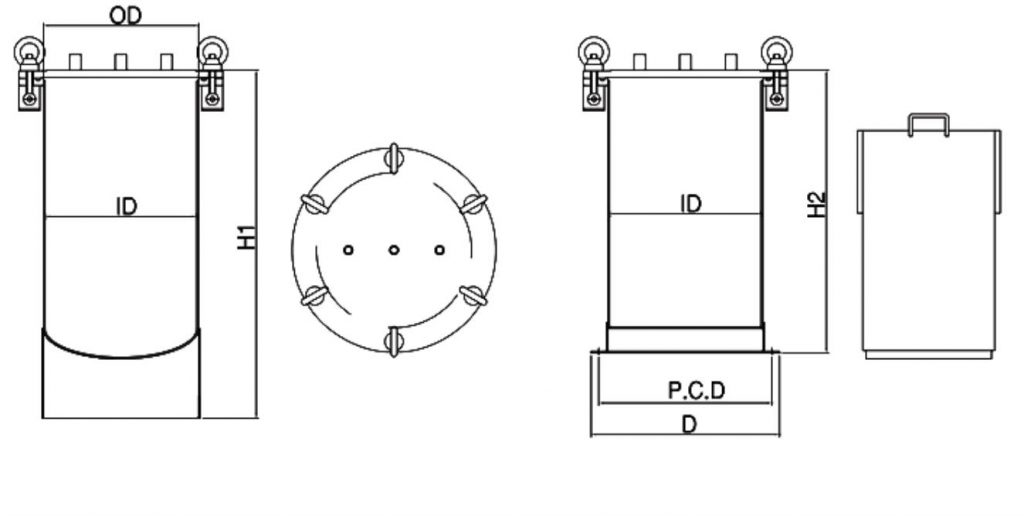

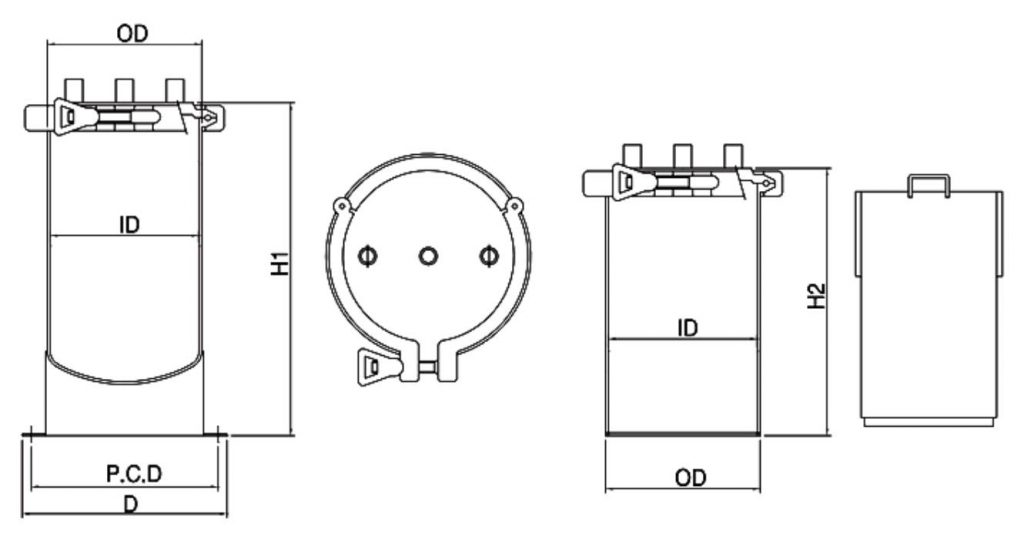

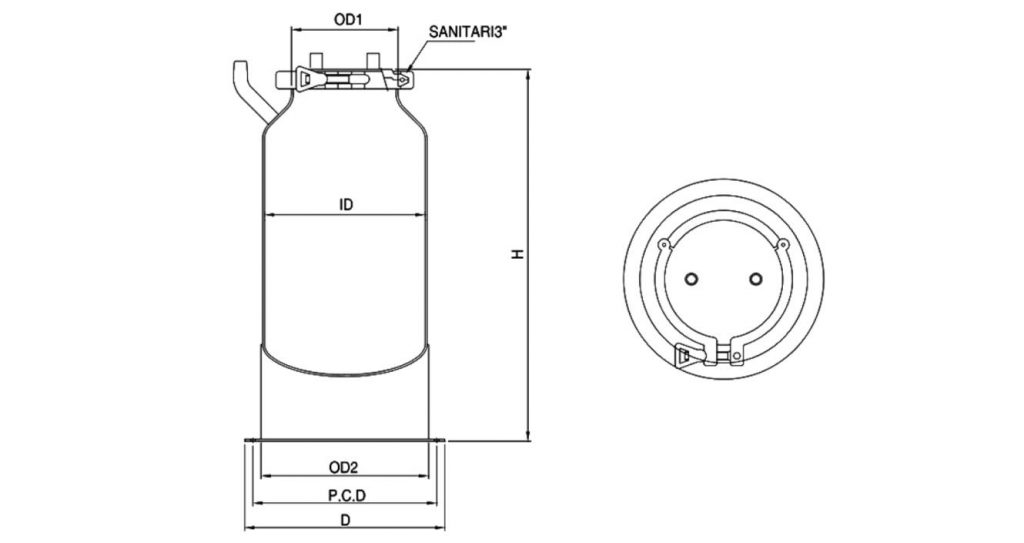

The PCP-20-10 High-Viscosity Pressure Pump is engineered for seamless dispensing of thick materials directly from 20L (5-gallon) pail containers. This industrial pail pump is designed to enhance productivity and minimize waste in high-demand applications.

Key Benefits of the PCP-20-10 High-Viscosity Pump:

- Direct 20L Pail Dispensing: Eliminate the need for material transfer and reduce contamination by dispensing directly from standard 20L pails. This direct pail dispensing pump streamlines your workflow.

- Bubble-Free High-Viscosity Dispensing: Maintain material integrity with our bubble-free operation. This feature prevents air entrapment, ensuring consistent and high-quality dispensing of viscous fluids.

- Compact and Efficient Design: The PCP-20-10 is designed for easy integration into any workspace. Its compact and lightweight design makes it ideal for applications with limited space.

- Precision Application Valve: Achieve accurate and consistent dispensing with our self-developed simultaneous application valve. This precision dispensing pump enhances productivity and quality.

- Durable and Reliable Performance: Built to withstand high-pressure applications, the PCP-20-10 ensures minimal wear and long-lasting performance. Ideal for sealing, bonding, and molding processes.

Product Specifications:

Model PCP-20-10 Pump Sending Ratio 10:1, 20:1(For high pressure) Applying Viscosity 10,000~400,000cps Air Pressure 1~7bar Air Consumption 80ml/min(max Applying Container – Power AC220V 50/60Hz(110V:Option)

Why Choose the PCP-20-10 for High-Volume High-Viscosity Applications?

This 20L pail pump is specifically designed for industries requiring efficient and reliable dispensing of high-viscosity materials in large volumes. Its direct pail dispensing and precise application valve make it an essential tool for demanding production environments.

Key Features for Optimal Performance:

- Direct Pail System: Simplifies material handling and reduces waste.

- Bubble-Free Operation: Ensures consistent material quality.

- Compact Design: Facilitates easy installation and integration.

- Precision Valve: Provides accurate and consistent dispensing.

- High-Pressure Capability: For reliable dispensing of thick fluids.

- 20L pail compatibility: designed for industry standard 5 gallon pails.

Applications:

- Industrial Sealing and Bonding

- Molding Processes

- Adhesive Dispensing in Manufacturing

- High-Volume Material Application

- Any application requiring high-viscosity material dispensing from 20L pails.