Pressure Tank BMT Type

Discover BMT Large Capacity Tanks for efficient fluid handling. Choose from various sizes and material options (SUS, PE, Teflon). Blaze offers custom engineering support. Contact us!

In the fast-paced world of industrial operations, efficiency and reliability are paramount. When it comes to handling large volumes of fluids under high pressure, having the right equipment is not just an advantage – it’s a necessity. That’s where BMT Large Capacity Tanks come into play, and Blaze is your trusted partner in bringing these powerful solutions to your projects.

Understanding the Power of BMT Large Capacity Tanks

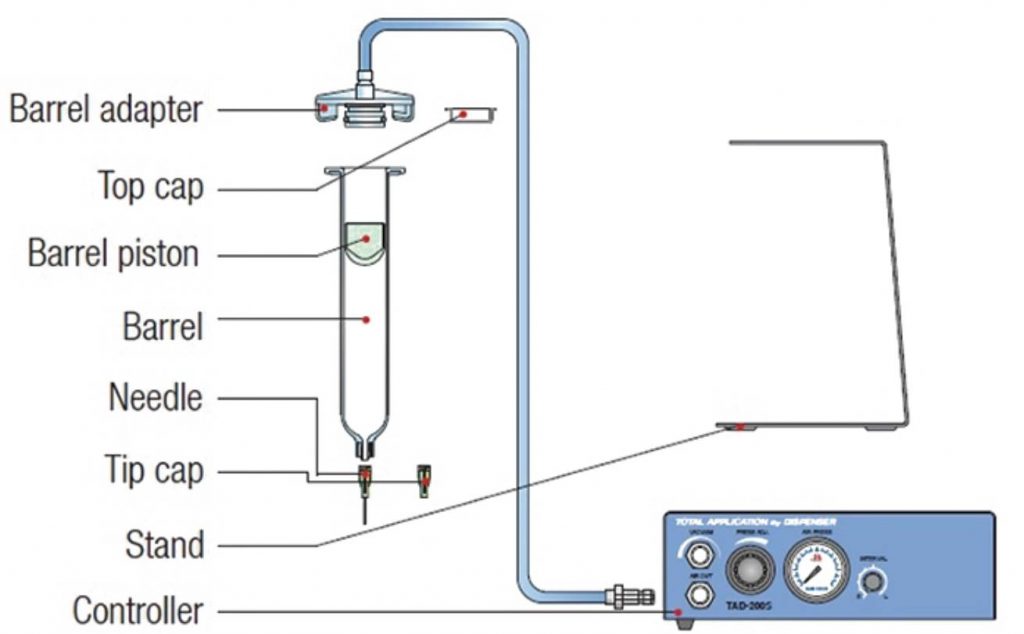

BMT Large Capacity Tanks are engineered for demanding industrial applications requiring the storage and dispensing of significant fluid volumes under high pressure. These tanks are designed with user convenience and operational efficiency in mind.

Key Features and Benefits:

- Direct Inner Container Mounting: The innovative hinge clamp method allows for the direct mounting of inner containers, simplifying operations and reducing downtime.

- High-Pressure Compatibility: These tanks are built to withstand high-pressure pneumatics, making them ideal for a wide range of industrial processes.

- Large Capacity: Available in various sizes (from 50L to 1000L), BMT tanks cater to diverse volume requirements, ensuring you have the right capacity for your specific needs.

- Robust Construction: Made with high-quality materials like SUS, PE, Teflon, and Teflon coating, these tanks offer exceptional durability and chemical resistance.

Applications Across Industries

BMT Large Capacity Tanks are versatile and find applications in various industries, including:

- Chemical Processing: Safely store and dispense chemicals under high pressure.

- Manufacturing: Efficiently handle large volumes of fluids in production processes.

- Pharmaceuticals: Ensure precise and contamination-free fluid handling.

- Food and Beverage: Maintain hygiene and efficiency in fluid storage and dispensing.

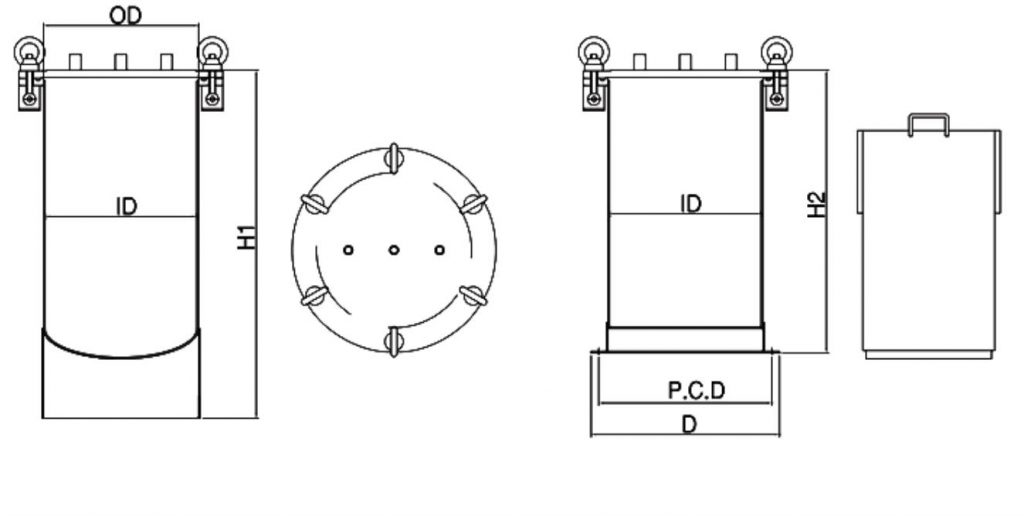

Product specifications:

MODEL Capacity H1 (mm) H2 (mm) OD (mm) ID (mm) D (mm) P,C,D (mm) Bolt Hole Size Options BMT 5 L 366 266 165 159 225 205 M10-4EA SUS,

PE,

TeflonBMT 10 L 416 316 216 210 276 256 M12-4EA BMT 20 L 566 416 255 249 315 295 M12-6EA BMT 40 L 566 416 350 344 410 390 M12-8EA BMT 100 L 776 596 460 454 520 500 M12-16EA

Straight Type

Flange Type

- Product Selection: Consultations to identify the optimal BMT tank for your specific liquid compatibility and volume requirements.

- Custom Engineering: Adapting BMT tanks or designing custom solutions for unique needs, including material and size modifications.

- System Integration: Seamlessly integrate BMT tanks into your existing production lines.

- Technical Support: Expert guidance and support for installation and maintenance.