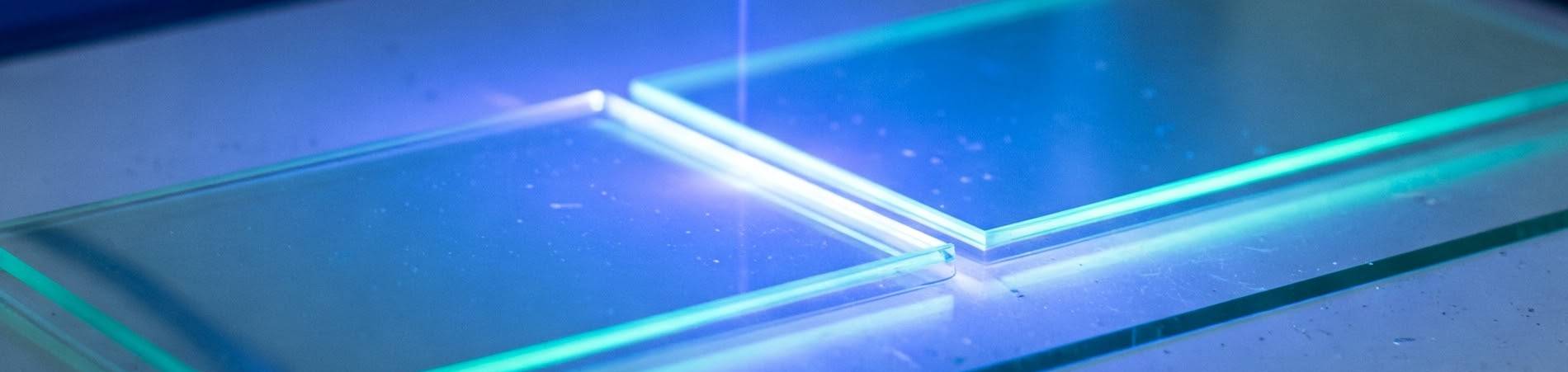

UV glass bonding: creating seamless, strong bonds for windshields, touchscreens, and more. Explore the benefits of this fast, efficient, and versatile technology.

Glass UV bonding is a revolutionary bonding technology that uses ultraviolet (UV) light to cure a special adhesive between two pieces of glass. This creates a strong, durable, and invisible bond that is virtually indistinguishable from the surrounding glass.

What is Glass UV Bonding?

Glass UV bonding is a process that uses UV light to cure a special adhesive between two pieces of glass. This creates a strong, durable, and invisible bond that is virtually indistinguishable from the surrounding glass.

How Does Glass UV Bonding Work?

Glass UV bonding works by applying a thin layer of UV-curable adhesive to one or both of the glass surfaces. The two pieces of glass are then placed together and exposed to UV light. The UV light causes the adhesive to polymerize, or harden, creating a strong bond between the two pieces of glass.

Benefits of Glass UV Bonding

Glass UV bonding has a number of advantages over traditional bonding methods, such as mechanical fasteners or glues. These advantages include:

- Strong and durable bond: Glass UV bonding creates a strong and durable bond that is resistant to moisture, chemicals, and temperature extremes.

- Invisible bond: The bond created by glass UV bonding is virtually invisible, making it ideal for applications where aesthetics are important.

- Fast and efficient: Glass UV bonding is a fast and efficient process that can be used to bond large or small pieces of glass.

- Versatile: Glass UV bonding can be used to bond a variety of different types of glass, including soda-lime glass, borosilicate glass, and aluminosilicate glass.

Applications of Glass UV Bonding

Glass UV bonding is used in a variety of industries, including:

- Automotive: Glass UV bonding is used to bond windshields, rearview mirrors, and other automotive glass components.

- Consumer electronics: Glass UV bonding is used to bond touchscreens, display covers, and other components in smartphones, tablets, and other electronic devices.

- Medical devices: Glass UV bonding is used to bond components in medical devices, such as implantable devices and diagnostic equipment.

- Architectural: Glass UV bonding is used to bond glass panels in buildings and other structures.

The Future of Glass UV Bonding

Glass UV bonding is a rapidly evolving technology that is expected to play an increasingly important role in a variety of industries. As the technology continues to develop, we can expect to see even more innovative and exciting applications of glass UV bonding.

Incure Quad-cure™ Series Core Products - Glass, Crystals

Incure Quad-cure™ 1931: UV/Visible/Heat Cure Bonder (Metals/Glass/Ceramics) – High Strength, Low Shrink (Weatherproof, Temp/Moisture Resist)

Incure Quad-cure™ 1933: Multi-Cure (UV/LED/Heat) Bonder (Metals/Glass) – High Strength, Tack-Free, Temp/Moisture Resist

Incure Quad-cure™ Series Core Products - Glass + Metal)

Incure Quad-cure™ 9254: UV/Visible/Heat Cure Bonder (Metals/Glass) – High Strength (Mid Viscosity, Low Shrink, Vibration Damping)

Incure Quad-cure™ 9263: UV/Visible/Heat Cure Bonder (Metals/Glass) – High Strength (Low Viscosity, Low Shrink, Vibration Damping)

Incure Quad-cure™ 9245: UV/Visible/Heat Cure Bonder (Metals/Glass) – High Strength (High Viscosity, Low Shrink, Vibration Damping)

Incure MG: Multi-Cure (UV/Visible/Heat) Metal/Glass Bonder (High Strength, Gap Filling, Vibration Damping)

Incure Quad-cure™ 1922: Multi-Cure (UV/LED/Heat) Bonder (Metals/Glass/Ceramics) – High Strength, Low Shrink (Weatherproof, Temp/Moisture Resist)

Incure Uni-Weld™ Series Core Products - Glass + Metal + Plastic

Incure Uni-Weld™ 1203: Tack-Free UV Bonder (High Strength) – Metals/Glass/Ceramics (Low Shrink, Temp/Moisture Resist, Vibration Damping)

Incure Uni-Weld™ 1238: High Strength UV Bonder (Metals/Glass) – Fast Cure, Low Shrink/Water Absorp. (Ideal for Stainless Steel/Glass)

Incure Uni-Weld™ 1471: Industrial UV Bonder (Very Low Viscosity, High Strength) – Multi-Substrate (Differs Hardness)

Package Size: 10 ml syringe / 30 ml syringe / 30 ml squeeze bottle / 100 ml squeeze bottle / 250 ml squeeze bottle / 1 kg Bottle / 1 Gallon Pail / 2 Gallon Pail / 5 Gallon Pail

Last updated on March 3rd, 2025 at 12:16 pm