Boost precision and efficiency in your manufacturing with UV masking resins! Learn how these light-curable materials offer unparalleled accuracy and speed compared to traditional masking. Discover the benefits, applications, and how Incure’s custom formulations and expert support can illuminate your projects.

In today’s fast-paced manufacturing world, precision and efficiency are paramount. UV masking resins have emerged as a game-changer, offering unparalleled accuracy and speed in a variety of applications. This blog post will delve into the world of UV masking resins, exploring their benefits, applications, and how Incure, a leading adhesive manufacturer, can be your partner in achieving project success.

What are UV Masking Resins?

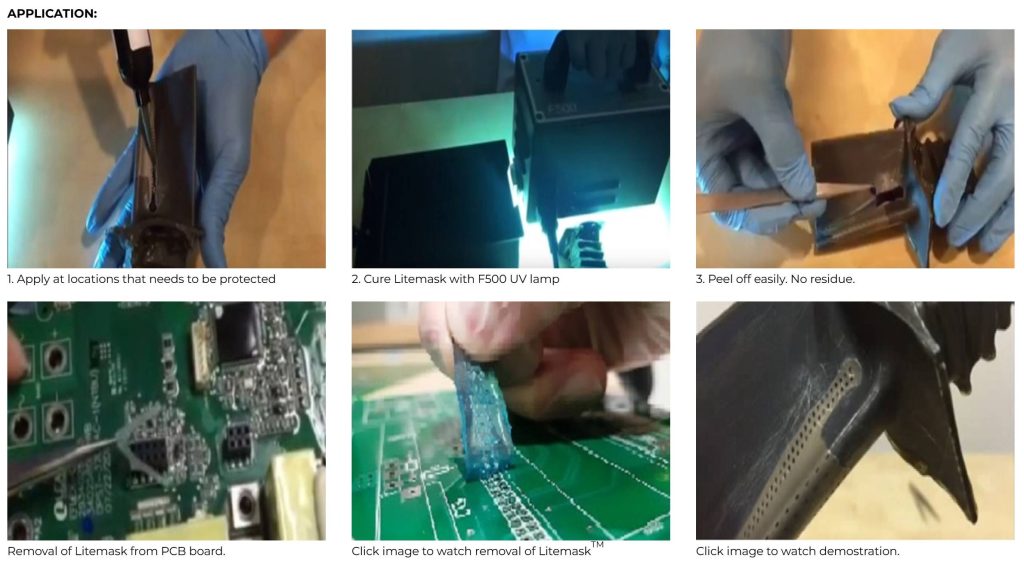

UV masking resins are specialized materials designed to temporarily protect specific areas of a substrate during processing. Unlike traditional masking methods, these resins are applied in liquid form and then cured using ultraviolet (UV) light. This curing process transforms the liquid resin into a solid, protective layer, allowing for precise masking and preventing unwanted exposure to chemicals, coatings, or other treatments. Once the processing is complete, the UV masking resin can be easily removed, leaving behind a clean and precisely defined area.

The Advantages of Using UV Masking Resins:

- Precision: UV masking resins allow for extremely fine detail and sharp edges, ideal for intricate designs and complex geometries.

- Speed and Efficiency: UV curing is a rapid process, significantly reducing masking time compared to traditional methods. This translates to increased production throughput and lower labor costs.

- Versatility: UV masking resins are compatible with a wide range of substrates, including metals, plastics, glass, and ceramics. They can be used with various processing techniques, such as etching, plating, coating, and painting.

- Clean Removal: Properly formulated UV masking resins are designed for easy removal without leaving residue or damaging the underlying substrate.

- Cost-Effectiveness: While the initial investment in UV curing equipment might seem significant, the long-term cost savings due to increased efficiency, reduced labor, and minimized waste make UV masking resins a financially sound choice.

Incure Litemask™ Series Core Products Product Description Substrates Color Viscosity (cP) Tensile (psi) Hardness (Shore D) Elongation (%) 4201 Aerospace Grade, UV/Visible/Heat Cure, Low Viscosity, High Strength, Metal/Glass/Ceramics Masking, Low Shrinkage, Temp/Moisture Resistant High Performance

Metal/Glass/CeramicsSlight Tint 130 7,400 – 10,000 D75 – D85 4 4272 Aerospace Grade, UV/Visible/Heat Cure, Low Viscosity, High Strength, Metal/Glass/Ceramics Masking, Low Shrinkage, Temp/Moisture Resistant High Performance

Metal/Glass/CeramicsSlight Tint 400 9,700 – 10,900 D77 – D87 4 4153 Ultra-Clear, Low Viscosity, UV/Visible/LED/Activator/Heat Cure, High Strength, Metal-Glass Mask, Burn-Off Removal, Tack-Free, Jewelry Use High Performance

Metal/Glass/CeramicsSlightly Translucent 700 7,000 – 8,400 D80 – D90 33 3148 Ultra-Clean, Tough, Chemical Stain/Scratch Protection, No Residue, Critical Surface Protection High Performance

Metal/Glass/CeramicsDark Blue 6,000 4,600 – 5,300 D49 – D59 250 1123G Very High Viscosity, Clear Peelable Mask, Temporary Protection, Soldering/Sand-blasting Protection, Hot Water Removal, High Elongation High Strength,

Multi-SubstratesClear Gel 5,000 – 6,900 D67 – D77 300 4139 UV/Visible/Heat Cure, Good Adhesion to Metals/Glass, Aerospace Turbine Blade Protection, Chemical Cleaning Protection High Performance

Metal/Glass/CeramicsClear 24,000 9,800 – 16,000 D75 – D85 55 4139G UV/Visible/Heat Cure, Good Adhesion to Metals/Glass, Aerospace Turbine Blade Protection, Chemical Cleaning Protection High Performance

Metal/Glass/CeramicsClear >1,000,000 9,800 – 16,000 D75 – D85 55 8177G Gel Form, Ultra-Clean Peelable, High Temp Mask, Electronics/Aerospace, Soft/Tough/Flexible, Chemical Stain/Burnt Mark Protection Peelable Clear Blue Gel 3,600 A15 – A25 184 8114VT Very High Viscosity, Ultra-Clean Peelable, High Temp Mask, Electronics/Aerospace, Soft/Tough/Flexible, Chemical Stain/Burnt Mark Protection Peelable Clear Transparent 25,000 100 – 1,600 D30 – D40 26 8188G Gel Form, Ultra-Clean Peelable, High Temp Mask, Electronics/Aerospace, Soft/Tough/Flexible, Chemical Stain/Burnt Mark Protection Peelable Clear Blue >1,000,000 4,500 D15 – D25 90 Above products are available in thicker versions: T (Thick), VT (Very Thick), G (Gel) Package Size: 10 ml syringe / 30 ml syringe / 30 ml squeeze bottle / 100 ml squeeze bottle / 250 ml squeeze bottle / 1 kg Bottle / 1 Gallon Pail / 2 Gallon Pail / 5 Gallon Pail

Common Applications of UV Masking Resins:

- Printed Circuit Boards (PCBs): Protecting specific areas during etching and plating processes.

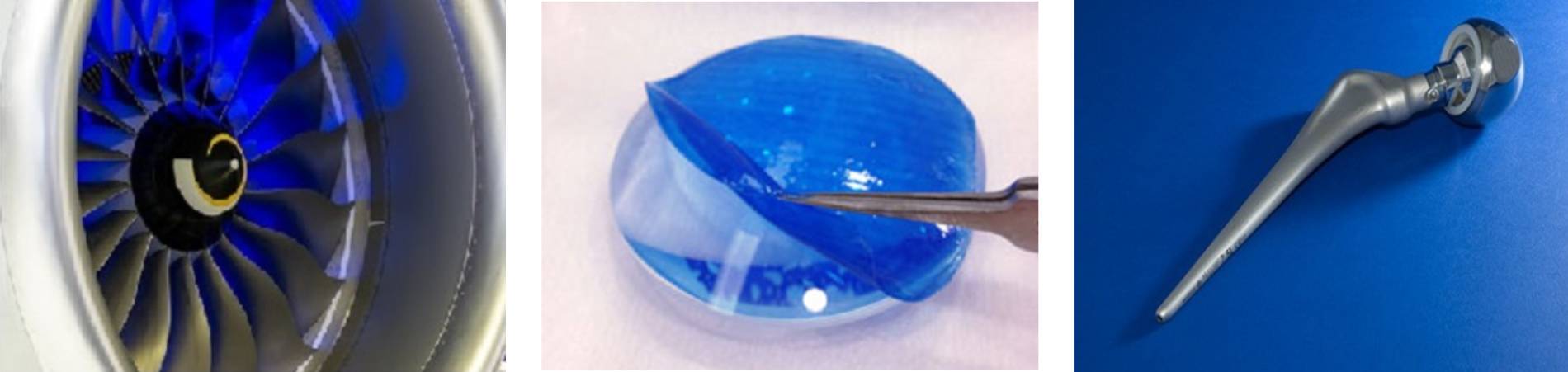

- Aerospace and Automotive: Masking components during painting, coating, and surface treatment.

- Medical Devices: Creating precise masks for intricate medical instruments and implants.

- Microelectronics: Protecting delicate components during manufacturing and assembly.

- General Industrial: Masking parts for various finishing processes, including powder coating, sandblasting, and chemical etching.

Incure: Your Partner in UV Masking Solutions:

Choosing the right UV masking resin is crucial for project success. Incure, a leading adhesive manufacturer, offers a comprehensive range of high-quality UV masking resins tailored to meet diverse application requirements. Here’s how Incure can help you:

- Extensive Product Portfolio: Incure offers a wide selection of UV masking resins with varying viscosities, cure speeds, and chemical resistances, ensuring the perfect match for your specific needs.

- Custom Formulations: Incure’s experienced chemists can work with you to develop custom formulations tailored to your unique substrate, processing method, and performance requirements.

- Technical Expertise: Incure provides expert technical support, helping you select the right product, optimize your curing process, and troubleshoot any challenges you may encounter.

- Quality Assurance: Incure is committed to delivering high-quality products that meet stringent industry standards. Their rigorous quality control processes ensure consistent performance and reliability.

- Collaborative Approach: Incure believes in building strong relationships with its customers. They work closely with you to understand your needs and provide personalized solutions.

Choosing the Right UV Masking Resin:

Selecting the appropriate UV masking resin involves considering several factors:

- Substrate Material: The resin must be compatible with the substrate to ensure proper adhesion and prevent damage.

- Processing Method: The resin should be resistant to the chemicals or processes used during manufacturing.

- Cure Speed: The desired cure speed will depend on production volume and process requirements.

- Viscosity: The viscosity of the resin will affect its application and coverage.

- Removal Method: The ease of removal is crucial to minimize production time and avoid damage to the substrate.

Conclusion:

UV masking resins offer a powerful solution for manufacturers seeking precision, speed, and efficiency in their processes. By partnering with a trusted adhesive manufacturer like Incure, you can leverage their expertise and access high-quality products to achieve optimal results. Contact Blaze today to discuss your project requirements and discover how Incure UV masking resins can illuminate your manufacturing processes. Unlock the power of light and take your projects to the next level with Incure.

Last updated on March 19th, 2025 at 06:08 am