Get detailed UV curing insights with EIT 2.0 UviCure®/Power Puck® II Profilers. Capture irradiance profiles for optimized process control & quality assurance.

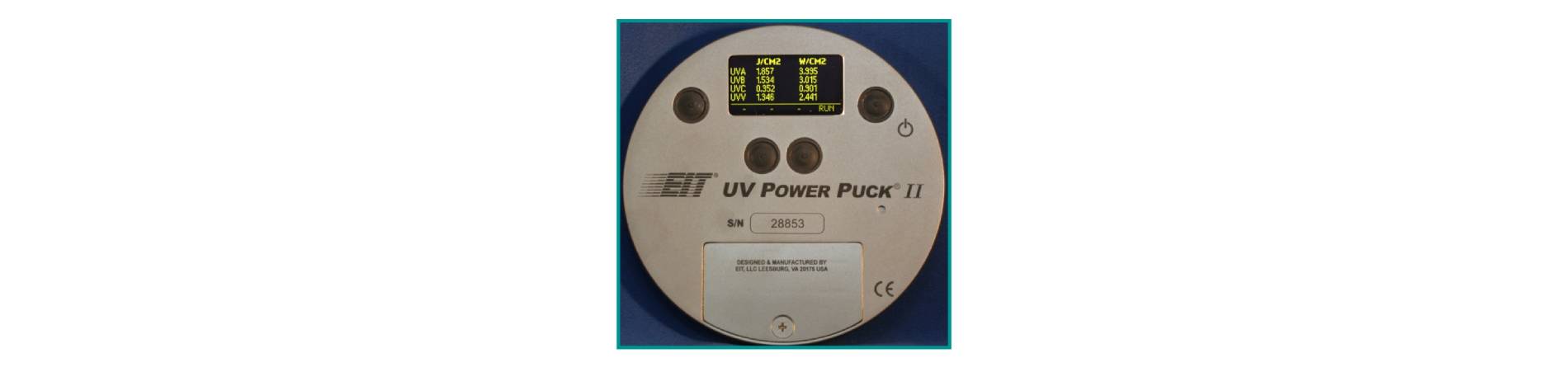

In today’s competitive manufacturing landscape, precision and data-driven decision-making are critical for success. When it comes to UV curing, simply measuring irradiance and energy might not be enough. To truly optimize your process and ensure consistent results, you need detailed profiling capabilities. Enter the EIT 2.0 UviCure® Plus II and UV Power Puck® II Profiler, advanced UV measurement solutions that provide in-depth irradiance profiles, empowering you to fine-tune your curing process like never before.

Why Irradiance Profiling Matters for UV Curing

Understanding the irradiance profile, or how UV intensity changes over time, is essential for:

- Optimizing Cure Times: Ensuring complete and consistent curing without overexposure.

- Identifying Lamp Issues: Detecting variations in lamp output and performance.

- Troubleshooting Process Problems: Quickly pinpointing the root cause of curing inconsistencies.

- Improving Quality Control: Maintaining consistent product quality and reducing defects.

- Validating Cure Parameters: Ensuring compliance with industry standards and customer specifications.

Introducing the EIT 2.0 UviCure® Plus II & UV Power Puck® II Profiler: Advanced UV Analysis

These profiler versions of the renowned EIT 2.0 radiometers provide all the standard measurement features, plus the ability to capture and analyze detailed irradiance profiles.

Key Features and Benefits of the Profiler Options:

- Irradiance Profiling: Capture and analyze UV irradiance as a function of time.

- Data Transfer to Computer: Transfer profile data via USB for in-depth analysis and reporting.

- Adjustable Sample Rates: Choose between 128 Hz and 2048 Hz for varying levels of detail.

- Quick and Easy Identification of Issues: Instantly visualize changes in lamp output, cure times, and UV intensity.

- Improved Process Control: Fine-tune your curing parameters for optimal performance.

- Enhanced Quality Assurance: Ensure consistent curing and reduce product defects.

- Predictive Maintenance: Identify potential lamp failures before they impact production.

Applications for the EIT 2.0 UviCure® Plus II & UV Power Puck® II Profiler:

- Advanced R&D: Developing and optimizing new UV curing processes.

- Laboratory Testing: Characterizing UV sources and materials.

- Troubleshooting Complex Curing Issues: Identifying and resolving process problems.

- Quality Control and Validation: Ensuring consistent curing and compliance with standards.

- Process Optimization: Fine-tuning curing parameters for maximum efficiency.

Why Choose the EIT 2.0 UviCure® Plus II & UV Power Puck® II Profiler?

- Unprecedented Insight: Gain a deeper understanding of your UV curing process.

- Advanced Analysis Capabilities: Capture and analyze detailed irradiance profiles.

- Easy Data Transfer: Transfer data to a computer for in-depth analysis and reporting.

- Robust and Reliable: Built to withstand demanding industrial environments.

Take Your UV Curing Process to the Next Level.

Invest in the EIT 2.0 UviCure® Plus II or UV Power Puck® II Profiler and unlock the full potential of your UV curing process. Contact us today to learn more about how these advanced profilers can benefit your manufacturing operations and help you achieve unparalleled levels of precision and efficiency.